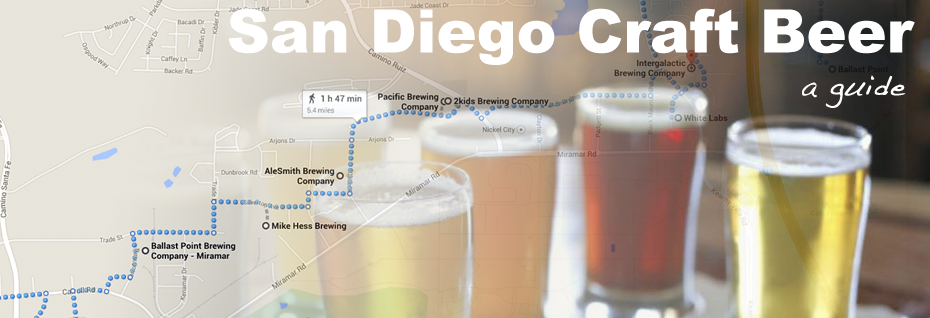

Here are three San Diego areas with highly concentrated breweries - all within 7 miles of each other - so that you can do a walking tour. You may choose to visit all indicated on the map or just a few. Click on the name to see the route.

Thursday, January 8, 2015

Wednesday, January 7, 2015

How to Homebrew

My friend is an award-winning homebrewer. I also tried his beers, which are excellent. This is his advice on how to get started: what equipment you will need and the process, with my own additions.

There are different pieces of equipment that you will need depending on what type of brewing that you choose to do. I'll go from easiest to most difficult. All methods assume you'll be making 5 gallon batches. First, here are the basic steps to the brewing process:

There are different pieces of equipment that you will need depending on what type of brewing that you choose to do. I'll go from easiest to most difficult. All methods assume you'll be making 5 gallon batches. First, here are the basic steps to the brewing process:

- Mashing (only for all grain)

- Boiling of wort (unfermented beer) and addition of hops

- Cooling of wort

- Fermentation

- Packaging (bottling or keging)

- Drinking!!

Methods:

1) Boil Extract

With this method, you use a malt extract (which comes in either a syrupy liquid or dry, powdered form), make a strong solution with it, boil it while adding hops, and then add back water at the end to make the full beer volume. You can also steep actual crushed barley grains in a muslin bag in the boil to add complexity. This is a partial volume boil extract, but you can also boil your full wort volume, a process called full volume boil extract; but instead of a 5 gallon pot, you'd need a 10 gallon pot. Equipment needed:

- 5 gallon aluminum or stainless steel pot

- Muslin bags

- Fermenter. This can be a 6 gallon food grade plastic bucket, glass carboy, or Better Bottle. I use glass carboys for fermentation because they don't scratch, which can provide a nice little nestling place for bacteria. I bought my carboys on craigslist. Plastic buckets are okay as long as they're relatively new and you're gentle with cleaning, i.e. don't use abrasive sponges.

- Method for chilling the wort. The most rudimentary method (which I still use) is ice bath immersion. For this, you can use a sink or a container that is large enough to contain both the pot and ~20 lbs. of ice. If you want to get more fancy, you can chill via coiled convective heat exchanger or plate geometry heat exchanger (this requires a small pump and a pot with a valve and barbed fitting at the bottom).

2) All Grain

The full volume boil all grain is the method that I employ. Instead of an extract, you use raw, crushed, malted barley grains to create the wort in the mash. It creates an arguably better product, you have more parameters of freedom for recipe formulation, and to me it's more rewarding. However it is much more complicated than extract brewing and requires more equipment and time per batch. In addition to the previously mentioned equipment, you'll need:

The full volume boil all grain is the method that I employ. Instead of an extract, you use raw, crushed, malted barley grains to create the wort in the mash. It creates an arguably better product, you have more parameters of freedom for recipe formulation, and to me it's more rewarding. However it is much more complicated than extract brewing and requires more equipment and time per batch. In addition to the previously mentioned equipment, you'll need:

- 10 gallon aluminum or stainless steel pot

- Mash tun. I use a modified 10 gallon water cooler. The process for making one can be found here

- A large enough pot or enough pots to hold ~4 gallons of liquid

Other Equipment:

For packaging the beer, you'll need the same equipment regardless of brewing method. You'll need:

For packaging the beer, you'll need the same equipment regardless of brewing method. You'll need:

- Bottling bucket. This is a food grade plastic bucket with a hole and spout at the bottom.

- Capper

- Bottles and caps

- Bottle tree

- Bottle squirter for sanitizing the bottles

Other miscellaneous items that you will need:

- Bung and airlock for the fermenter

- Kitchen scale that can measure to 0.25 oz. I like the digital ones

- Sanitizer. I prefer a no-rinse variety like Starsan

- Probe thermometer

- Racking cane or auto siphon with appropriate size food grade tubing

- Carboy brush if you use a carboy

These items can be procured at your local home brew store, online, or craigslist.

Subscribe to:

Posts (Atom)